Production Management

A systematic and modernized production management system is one of TED’s most trusted strengths. Based on advanced manufacturing principles, TED has established an efficient, agile, and intelligent production framework that ensures every step—from R&D to mass production—is executed with precision. Key processes are closely monitored to ensure products consistently meet the highest quality standards.

Core Strengths

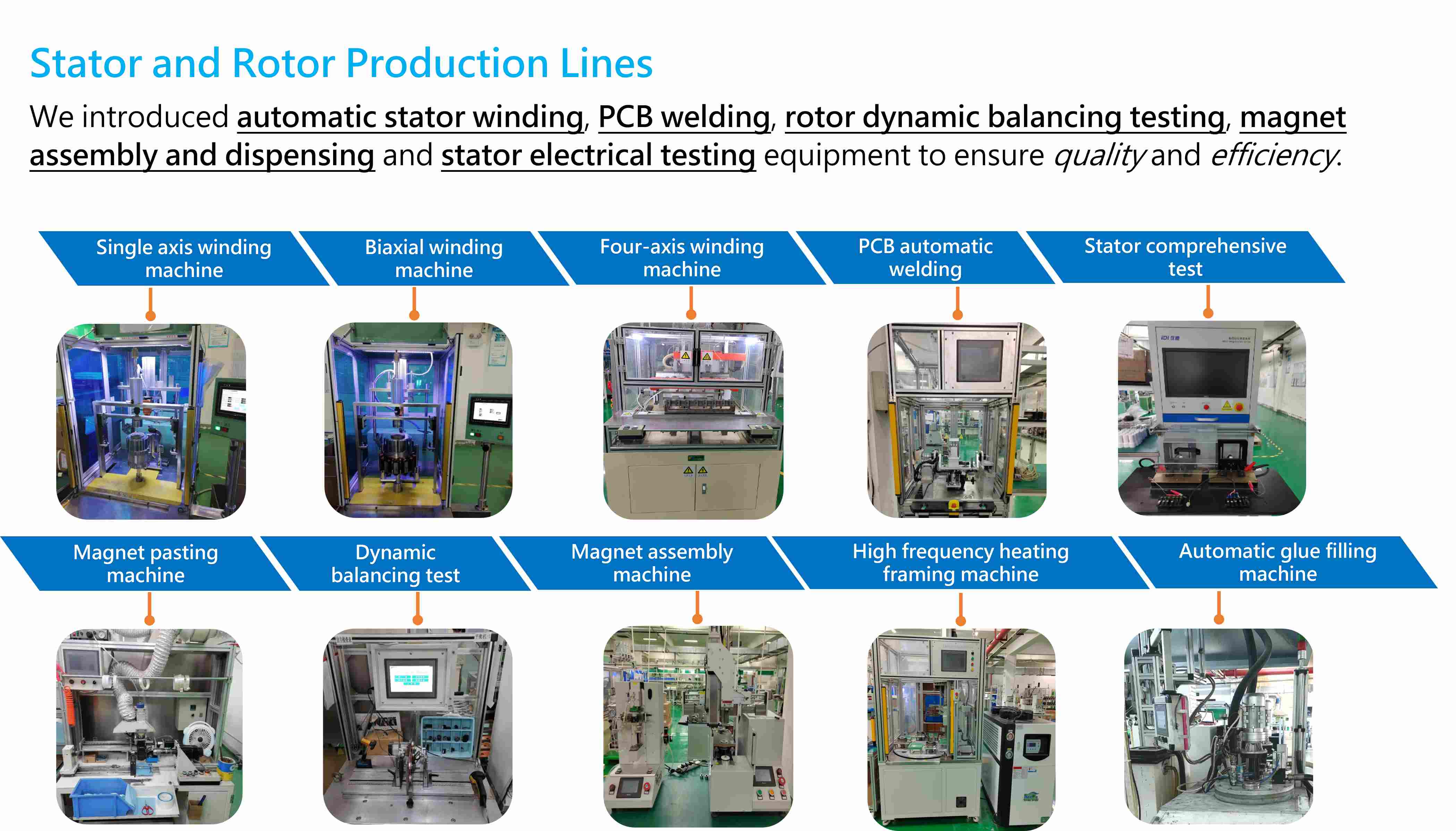

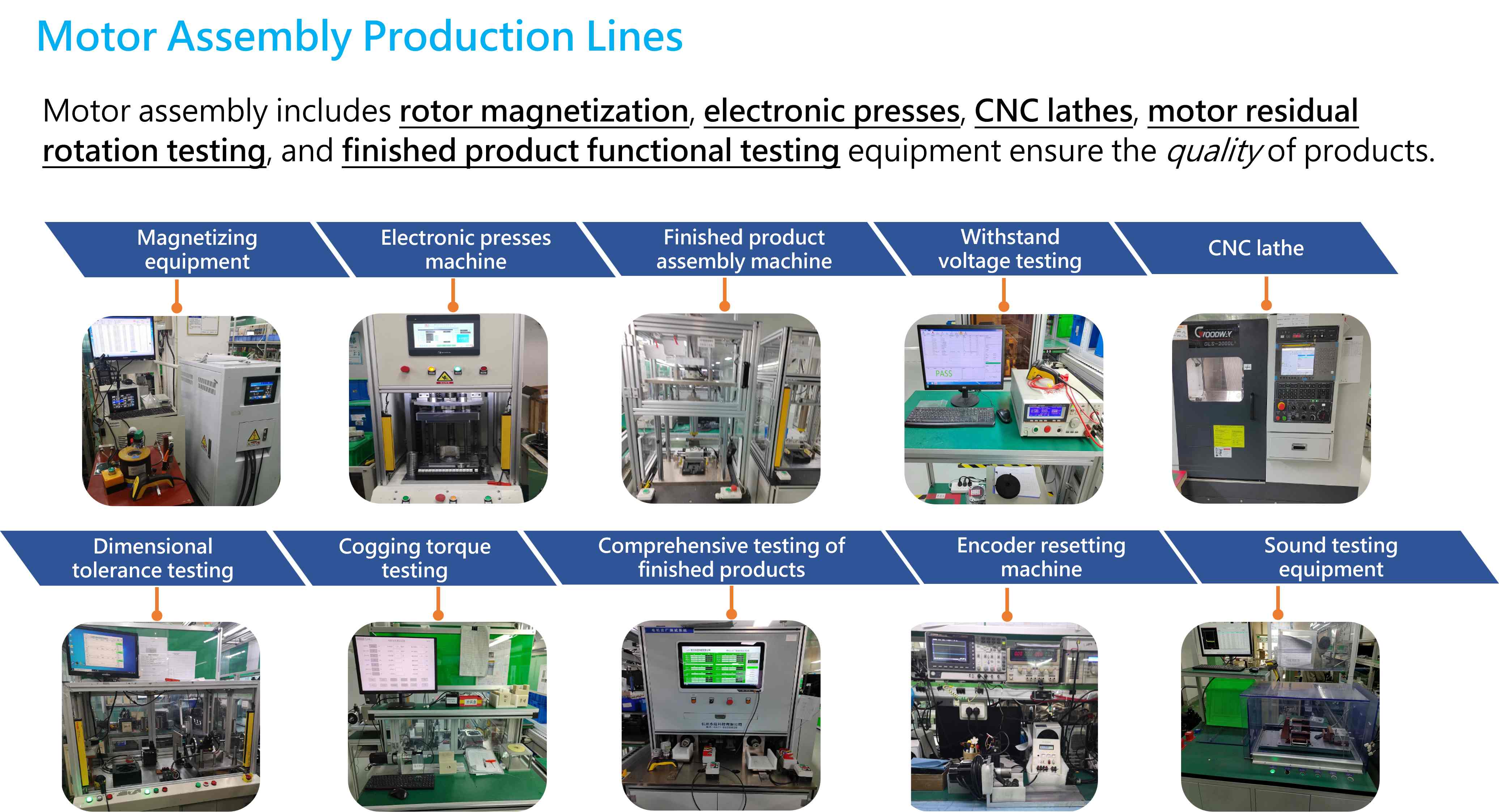

• Automation and Smart Manufacturing

Integration of advanced machinery and intelligent monitoring systems enables real-time production tracking and full traceability, ensuring product consistency and stability.

• Lean Manufacturing Management

Precise production scheduling reduces waste, shortens lead time, and maximizes resource utilization across all processes.

• Process Control

Comprehensive oversight of every stage—from material input, assembly, and testing to final packaging—ensures strict quality and process control. Data analytics and automation are applied to optimize cycle time and fine-tune process parameters for consistent high-performance manufacturing.

• Real-Time Data Monitoring

End-to-end monitoring of equipment status, process quality, and production efficiency enables immediate response to anomalies, ensuring stable and scalable mass production.

With a global manufacturing footprint and experienced management teams, TED accelerates production turnaround while providing precise process control and robust quality assurance—making us a reliable strategic partner to clients worldwide.